Every warehouse faces unique operational and logistical challenges. Warehouses tend to be incredibly busy and dangerous places, with workers, drivers, and others constantly on the move. Ensuring that your facility has the right warehouse material handling equipment can go a long way toward keeping everyone safe and productive. In this article, we will look closer at the top 17 warehouse material handling equipment items that your facility needs.

Warehouse Material Handling Equipment: Lifting, Transporting, and Storing

#1 – Pallet Jacks

Pallet jacks make it easy to transport heavy materials stacked on pallets. They feature two twin forks that slide underneath the pallet. A manual pallet jack requires the user to move the handle up and down with pumping force, which creates a hydraulic action that lifts the pallet.

#2 – Hand Trucks

Hand trucks are like pallet jacks, making transporting large items easier throughout the warehouse. A hand truck has a metal frame, toe plate, and handles. The operator slides the toe plate under an object and tilts the handles back, allowing him to wheel the object to another spot in the warehouse. Hand trucks are suited to move smaller objects than pallet jacks, and do not utilize hydraulic action.

#3 – Order Picker Forklift

An order picker forklift helps operators pick and transport materials needed to complete an order. The forklift lifts the operator to the same level as the inventory. This makes order picking more efficient and safer than using manual equipment like a ladder, which must be continuously moved and can easily shift on the operator.

#4 – Side loader Forklift

A side loader is a forklift designed for use in tight spaces, such as narrow aisles. However, it tends to be less maneuverable than standard forklifts. Depending on its design, the operator sits or stands in the machine. Side loaders can operate inside or outside and run on either electric, diesel, or propane.

#5 – Automated Guided Vehicles

An automated guided vehicle (AGV) is warehouse material handling equipment that travels autonomously throughout a warehouse. AGVs are used for tasks typically requiring a forklift, conveyor system, or even a manual cart. There are many different types of AGVs. They include:

- Automated guided carts (AGCs). The most basic type of AGVs, have minimal features and are used to transport a variety of materials in cross-docking, sorting, and storage applications.

- Forklift AGVs. Performs the same functions as a human-operated forklift but does not require an operator.

- Towing AGVs. Also known as tugger-automated guided vehicles, used to pull one or more load-carrying vehicles behind them like a train. Towing AGVs are generally used to transport heavy loads over longer distances.

- Unit Load Handlers. Typically used to transport single objects or units such as a pallet.

- Heavy Burden Carriers. Used in applications such as large assembly and plate transport. Some feature self-loading capabilities.

- Autonomous Mobile Robots (AMRs). AMRs are generally the most advanced AGVs. They are frequently equipped with intelligent navigation capabilities allowing them to dynamically navigate a warehouse and obstacles.

#6 – Cranes

Cranes are also commonly used warehouse material handling equipment. Warehouses may use a variety of cranes depending on their needs. Some commonly used cranes include stacker bridge cranes, gantry cranes, and jib cranes. Bridge cranes are used to move large and heavy objects. The crane spans a gap between two runway tracks and the hoist travels along the bridge. The design allows the hoist to access the area below to reach objects along three axes of movement.

Jib cranes are more stationary than bridge cranes. They have a hoist on a jib or boom that is attached to a stationary object such as a wall. If the boom is fixed, the jib crane will not have the ability to laterally rotate. Gantry cranes float back and forth between a gantry – an overhead frame structure from which equipment is suspended. Gantry cranes are more flexible than bridge cranes since they are supported by their own frames and are usually mounted on wheels or a track system.

#7 – Platform Trucks

A platform truck is simply a flat sheet of metal with wheels on the bottom and a handle on one end to allow the operator to push or pull the truck. Some types of platform trucks can hold more than 2,500 lbs. When operating the platform truck, the operator must be careful to push the truck and not the merchandise that is resting on it. This can cause the merchandise to fall off the truck, resulting in broken goods or accidents.

#8 – Conveyor Belts

A conveyor belt is a motor-driven belt that is part of a larger conveyor system. Operators place items onto the belt. The belt rotates, moving items to their end location in the conveyor system.

#9 – Reclaimers

A reclaimer is also part of a conveyor system. It is a machine with a rotating scoop positioned at one end of the conveyor system. The reclaimer gathers small, loose items and returns them to the belt to continue their journey.

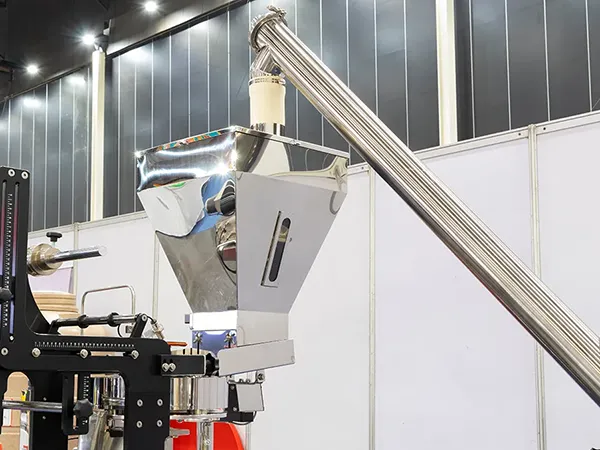

#10 – Hoppers

Hoppers resemble funnels and are used to handle small, loose items. Items are placed into the top of the hopper. Gravity causes them to move to the bottom. Hoppers are commonly used for waste disposal and recycling. Some hoppers are equipped with technology that allows them to automatically dump loads.

#11 – Bucket Elevators

Bucket elevators, or grain legs, are used to transport small items vertically. Small buckets attached to a belt scoop up material and transport them to the top, almost like a small ski lift. The elevator may need to be manually hand-cranked or use a motor to raise the buckets.

#12 – Silos

In agricultural settings, silos are used to store grain and silage and protect them from the elements. In other settings, they are used to store materials such as coal, wood, or food products. Silos help protect these valuable resources from the elements.

Warehouse Material Handling Equipment: Safety and Fall Protection

OSHA standards require that employees have access to the right personal protective equipment (PPE) and for many categories of PPE that it meet or be equivalent to the standards developed by the American National Standards Institute (ANSI).

OSHA also requires that fall protection be provided at elevations of four feet or more and when workers are required to work over dangerous machinery and equipment regardless of height.

#13 – Personal Protective Equipment (PPE)

Warehouse settings can be incredibly dangerous. Trucks and people are constantly coming and going, workers utilize a broad range of equipment, and elements such as heat, electricity, and chemicals can cause serious injuries. The right PPE helps protect workers and reduce the risk of serious injuries. PPE is a broad category but can include items such as hard hats, masks, gloves, and protective clothing.

#14 – Industrial and Portable Stairs

Prefabricated industrial stairs that are OSHA-compliant help keep your workers safe. Features such as handrails, guardrails, and slip-resistant decking help reduce falls and injuries.

#15 – Handrails

A portable aluminum safety railing system can protect employees from falls while working at heights. Railings should meet the latest OSHA requirements of 42” in height and feature non-penetrating railings that are simple to install and uninstall.

#16 – Safety Swing Gates

OSHA 1910.23 states that floor openings or platforms like stairway floor openings with passages through the railing must either provide a swinging gate or offset so that workers cannot walk directly into the opening. An adjustable swing gate that offers 20” of adjustability and a universal mounting system allows you to protect every passway in your facility with one SKU.

YellowGate products offer unmatched adjustability and portability to help you maintain a safe working environment in your facility. Contact a member of our team today to learn more about YellowGate products and how they can help address your facility’s safety needs.