When SmarterEveryDay’s Destin Sandlin gained rare access to film inside the Browns Ferry Nuclear Plant during an active reactor refueling operation, he captured something remarkable—not just the inner workings of nuclear power, but also the critical safety systems that make such operations possible.

Around the one-hour mark of the video, viewers can spot a YellowGate safety gate installed on the access bridge, positioned directly over the reactor core, preventing falls in one of the most demanding industrial environments on the planet.

Safety Where It Matters Most

Nuclear facilities represent the pinnacle of industrial safety requirements. Every component, every system, and every piece of equipment must meet rigorous standards, because failure is not an option. The presence of YellowGate safety gates in this environment speaks to the reliability and performance that define our product line.

Browns Ferry Nuclear Plant operates three reactor units under one roof, producing power for over 10 million people in the Tennessee Valley. During refueling operations, workers must access elevated platforms and bridges over open reactor vessels—areas where fall protection is absolutely critical. YellowGate’s self-closing design ensures consistent protection, even when workers are focused on complex, high-stakes tasks.

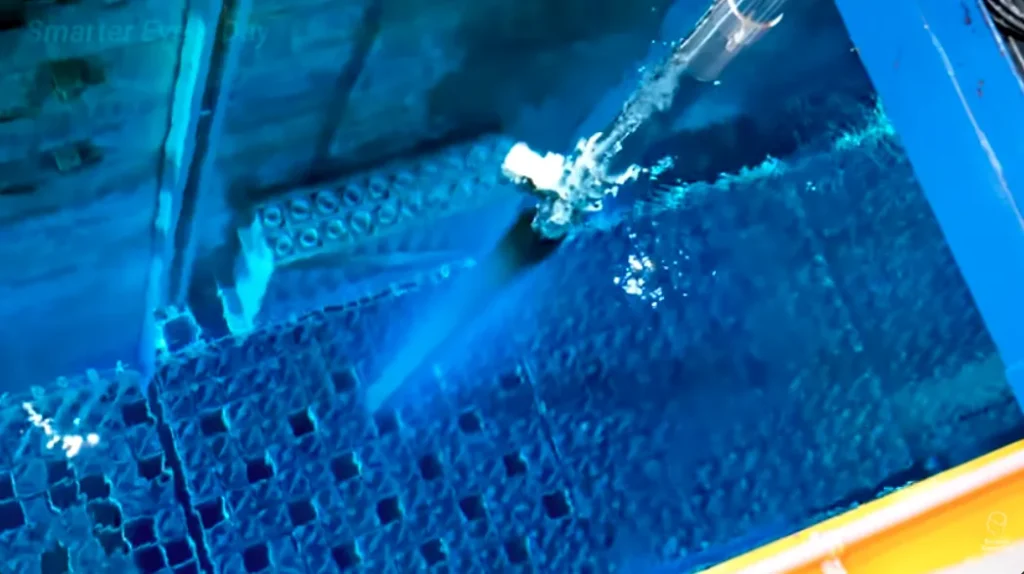

The Science Behind the Blue Glow

One fascinating detail from the video: unlike the cartoons where radioactive materials glow green, real nuclear reactors actually emit a brilliant blue light . This phenomenon, known as Cherenkov radiation, occurs when particles move through water faster than the speed of light in that medium, creating an electromagnetic shockwave visible to the human eye .

OSHA-Compliant Protection for Every Application

YellowGate safety gates are designed to meet or exceed OSHA 1910.28 and ANSI standards for fall protection and access control. Our self-closing, industrial-strength construction helps facilities maintain compliance in high-risk areas, including rooftops, loading docks, elevated platforms, and manufacturing spaces.

Key Features

Standard YellowGate Safety Gates provide adjustable protection from 21” to 37”, with a universal mounting system that eliminates custom fabrication . The self-closing mechanism ensures gates automatically return to a closed position, maintaining consistent fall protection even when operators are managing materials or equipment.

If YellowGate safety gates are trusted in nuclear power plants where precision, compliance, and safety are non-negotiable, they’ll handle whatever challenging environment your facility operates in.

Our gates serve critical applications across multiple sectors:

- Energy facilities including oil refineries, gas processing plants, and petrochemical terminals

- Chemical manufacturing and bulk loading operations

- Mining operations and mineral processing facilities

- Cold storage and food processing environments

- Manufacturing plants and distribution centers

Installation Made Simple

YellowGate’s universal bracket system simplifies deployment across ladders, walkways, loading docks, platforms, and equipment access points. The adjustable design fits various openings without cutting, welding, or drilling, making YellowGate ideal for both new construction and retrofit safety upgrades.

With 16 inches of adjustability and a universal mounting system, facilities can standardize on a single SKU to protect multiple passageways – eliminating the need to track measurements or mounting types for individual locations.